Quality

High-quality practices are a central aspect in Okmetic’s daily operations and management system. All our employees know that they are responsible for fulfilling our quality objectives.

Quality plays an essential role in the semiconductor industry. The products made with silicon wafers are microscopically small, and even the slightest defect may weaken their performance and reliability. Due to the fact that we operate at the very beginning of the electronics value chain, our operations have an impact on the entire process from the consumption of raw materials all the way to the lifetime of end-products.

We operate on the basis of fulfilling the high quality criteria by our customers every day. In practice, this is reflected, for example, as cleanliness requirements on our production site and continuous training of our personnel to improve quality awareness.

We have set up a quality organization in order to respond to the stringent requirements in the semiconductor industry even better.

We aim for the highest quality in all our operations. We have received a lot of positive feedback from our customers, for example, for our

- extremely motivated and skilled personnel

- flexibility of our production based on customer needs, and

- our Lean Six Sigma expertise.

At the moment, we are focusing on aspects such as developing product and process quality, improving the quality of customer experience and developing data security to an even higher level.

Our quality management is based on certified operational systems, development projects, and use of quality tools. We use the quality systems compliant with the general standards in the semiconductor industry. We require ISO 9001 certification even from our most significant contract manufacturers and suppliers.

Quality is the cornerstone of our operations

Okmetic’s quality policy

Our quality policy is based on four principles: skilled and motivated personnel, Right First Time approach, quality of our products and services, and customer satisfaction.

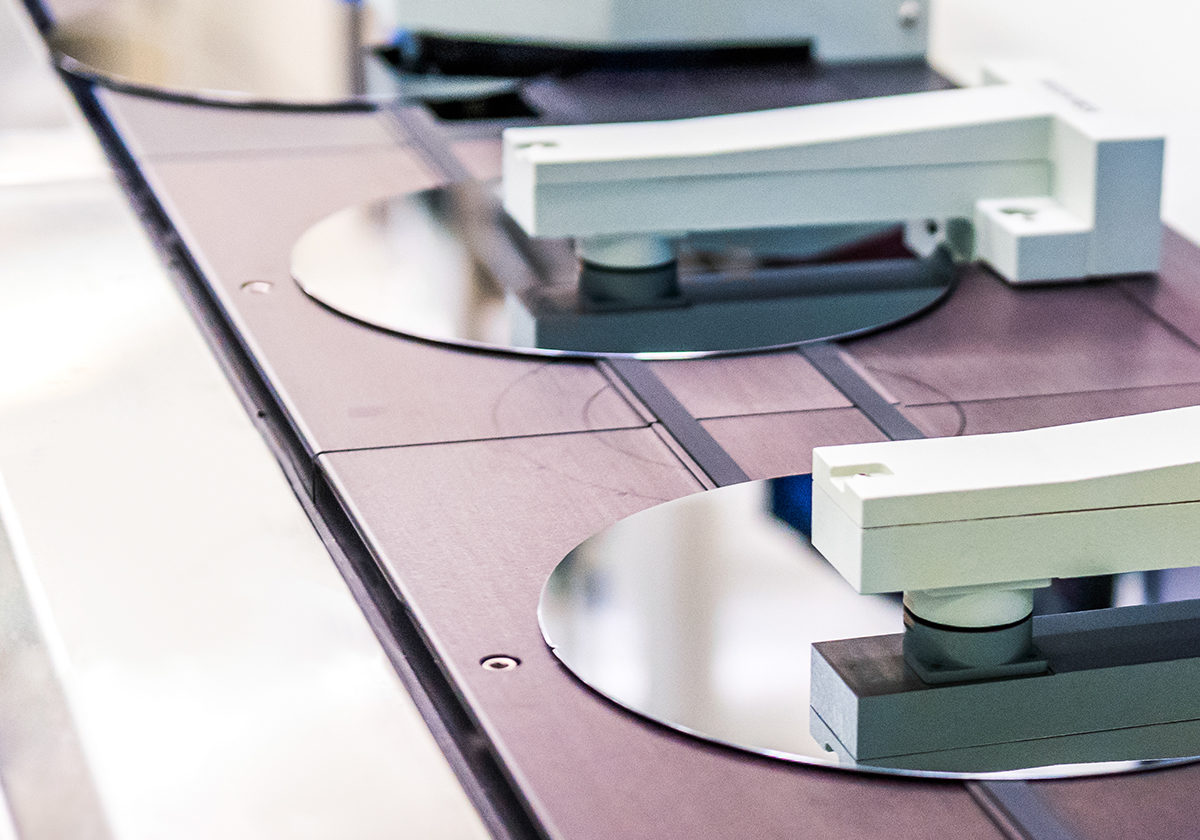

Quality of manufacturing process

Silicon wafers are subjected to strict technical quality requirements in terms of both cleanliness and ranges of mechanical and electronic properties. Therefore, manufacturing silicon wafers is a combination of precision, minimizing variations, and mass production volumes. Work phases at the end of the process are carried out in a clean room environment to ensure particle purity.

Quality tools

Statistical process control (SPC) is a central practice in the quality control of our production processes. Additionally, we utilize data analytics, artificial intelligence, as well as Six Sigma and Lean practices. The principles of 5S are also applied to all our operations.

Audits

Audits play a key role in continuous improvement. In addition to constantly reviewing how our quality system requirements are met, we regularly examine our processes as well as sufficiency and efficiency of our process controls. Even our customers test our quality systems. The annual averages have varied between 92% and 96% in recent years.

Quality certificates

We use quality systems compliant with ISO 9001:2015 and IATF 16949:2016 standards and environmental systems compliant with ISO 14001:2015 standard. We require ISO 9001 and ISO 14001:2015 certification even from our most significant contract manufacturers and suppliers.